Smooth and maintained roads are a paramount part of a developed infrastructure. Since the benefits of advanced infrastructure are many, road and pavement maintenance can’t be neglected.

Roads are constantly exposed to abrasion and wear, requiring specialized equipment to settle them. The success of milling largely depends on the tools employed for the job.

JYF Machinery specializes in making milling tools and wear parts for road mining. To discover more details about it, visit page and get your hands on the tools now.

Road Milling Tools That Fits Various Equipment

Following are the road milling tools that are applicable to various brands of equipment.

- Road Milling Teeth are Cutting tools designed to remove the top layer of road or pavement surfaces, ensuring a smoother and even foundation.

- Cold Planer Teeth are specialized cutting elements for cold planers, adept at removing deteriorated pavement layers and facilitating road repairs.

- Road Milling Bits are essential components of the milling drum. These bits assist in cutting and grinding surfaces during the road milling process.

- Asphalt Milling Teeth are tailored for asphalt surfaces. These teeth efficiently cut through and remove layers of asphalt during road maintenance.

- Road Milling Holders are like the backbone components that secure milling bits in place, providing stability to the milling drum and ensuring uniform milling depth.

Why Do Road Milling Tools by JYF Machinery Stand Out?

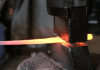

JYF Machinery takes precision to a new level with its road milling tools. Understanding the varying states of roads, these tools are meticulously crafted, ensuring the tooth or bit body possesses a compact internal structure. Achieving optimal tool toughness involves specialized heat treatments.

Constructed from high-quality cemented carbide and alloy steel, JYFMachinery products adhere strictly to ISO9001 standards. The company’s rigorous inspections span raw materials, processing procedures, and finished product shipments. JYF Machinery offers a comprehensive one-stop service catering to brand-specific needs—from rough forging to creating wear-resistant parts. Whether it’s milling teeth, seats, blocks, or other wear-resistant components, JYF Machinery stands poised to meet the all-encompassing requirements of brand customers in road milling tools.

Benefits of Quality Milling Tools

- Enhanced Efficiency: High-quality milling tools significantly improve the efficiency of the milling process. They cut through materials more effectively, reducing the time required to complete a project.

- Cost Savings: Investing in premium milling tools may seem like an upfront expense, but it pays off in the long run. Quality tools last longer, reducing the frequency of replacements and associated costs.

- Quality Surface Finish: The right milling tools contribute to a smoother surface finish. This improves the road’s or pavement’s aesthetics and enhances safety for drivers and pedestrians.

Conclusion

In the field of road and concrete pavement milling, the tools employed are the unsung heroes that determine the success of a project. Understanding the types of tools, their compatibility and the critical considerations during milling is essential for achieving optimal results. By investing in high-quality instruments, one not only ensures efficiency and cost-effectiveness but also contributes to the longevity and safety of our infrastructure.