When it comes to the exciting world of CNC machining magnesium with 3ERP, safety is our top priority. Just like wearing a helmet while riding a bike or putting on a seatbelt in a car, we take specific safety measures to make sure everyone involved is protected. In this journey of crafting incredible things with magnesium, we follow some simple but crucial safety tips.

From wearing the right gear to using specialized tools and ensuring good ventilation, these measures are like our superhero cape they keep us safe while we create amazing components. Let’s explore these safety tips, ensuring that our adventures in cnc machining magnesium are not just innovative but also secure for everyone.

Safety Tips of CNC Machining of Magnesium

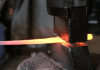

CNC machining of magnesium is a powerful technique, offering precision and efficiency in creating lightweight and robust components. However, it comes with safety considerations due to magnesium’s explosive nature. Here, we’ll explore simple yet crucial safety tips for CNC machining magnesium to ensure a secure working environment.

Ventilation Matters

Ventilation matters a lot when it comes to CNC machining magnesium. It’s all about making sure there’s enough fresh air flowing around. Why? When we machine magnesium, tiny bits of magnesium dust can be in the air, and that dust can be a bit flammable. Good ventilation helps to keep the air clean and prevents too much of that dust from hanging around. So we pay attention to having good airflow in the machining area.

Fire Prevention Precautions

Fire prevention precautions are super important when CNC machining magnesium. Since magnesium is flammable, we take extra steps to keep everything safe. We use special systems that can stop a fire before it gets big and use materials that don’t easily catch fire. It’s like having a superhero shield against flames! We also keep firefighting tools close by, like fire extinguishers, just in case we need them. It’s all about being smart and preventing problems before they even start.

Personal Protective Equipment (PPE)

Wearing the right gear, known as Personal Protective Equipment (PPE), is super important when CNC machining magnesium. It’s like wearing a superhero costume for safety! Operators wear safety glasses to protect their eyes, face shields to guard against sparks and special clothing that won’t catch fire easily. Think of it as getting ready for a cool adventure – but in the machining world. Sometimes, operators might need to wear a special mask, called a respirator, to make sure they don’t breathe in any tiny bits of magnesium.

Proper Tooling and Equipment

Using the right tools and equipment is a big deal when CNC machining magnesium. It’s like having the perfect set of tools for a specific job. We make sure our tools are designed especially for working with magnesium to avoid any sparks or overheating, which could be a bit risky. We regularly check and take care of our tools to make sure they’re in top-notch condition. It’s all about having the right gear and keeping it in great shape to create awesome things with magnesium while keeping everyone.

Training and Certification

Getting the right training and certification is like becoming a skilled superhero in the world of CNC machining magnesium with 3ERP. Operators go through special training to learn how to handle magnesium safely and operate the CNC machinery. Being certified means they’ve officially proven they know the ropes. This is super important because it ensures that everyone working with magnesium at 3ERP is like a superhero with the right knowledge and abilities, making the workplace safer for everyone involved

Control the Dust

Controlling the dust is super important when CNC machining magnesium. Magnesium dust can be risky, so it’s crucial to use dust collection systems to keep the air clean and minimize floating particles. By doing this, we not only create a safer workspace but also help maintain the CNC machinery’s efficiency. Keeping the machining area dust-free ensures that everyone working with magnesium is breathing clean air, reducing the chances of any potential hazards. It’s a good practice for the equipment’s longevity, ensuring it stays in top-notch condition.

Emergency Preparedness

Being ready for emergencies is a must when CNC machining magnesium. Emergency preparedness means having clear plans for unexpected situations, like fires or accidents. Being prepared also means having firefighting equipment on hand, like fire extinguishers, just in case. When everyone knows the emergency procedures and can act swiftly, it helps keep the workplace safe and minimizes any potential harm. So making sure we’re ready for the unexpected is a top priority to ensure the well-being of everyone.

Regular Inspections

Regular inspections play a crucial role in keeping things safe when CNC machining magnesium with 3ERP. It’s like giving the machinery and the workspace a check-up to make sure everything is working as it should. We can catch problems early on and fix them before they become bigger concerns. This helps in maintaining a secure working space and ensures that the CNC machinery is in good shape. It’s like giving our equipment a little TLC to keep everything running smoothly and safely.

Conclusion

While CNC machining magnesium offers numerous advantages, prioritizing safety is non-negotiable. By following these simple safety tips, operators working with magnesium can ensure a secure environment, minimize risks, and make the most of the benefits that CNC machining with magnesium has to offer. Remember, a commitment to safety is an investment in the well-being of everyone involved in the machining process.